Rotation innovation: Oxnard firm cranks out new take on rotary engines

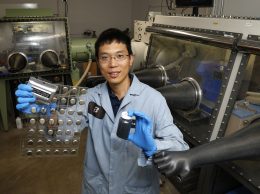

From left, GoTek Energy’s Steve Herbruck and Scott Farrenkopf show off a test prototype of the company’s new rotary engine. Designed to address problems with existing rotary engines, the unit can use nearly any combustible fuel. (Stephen Nellis photo)

An Oxnard-based startup is developing a fuel-efficient rotary engine that could one day run cars and trucks off nearly any combustible fuel.

GoTek Energy, currently housed at an aerospace machine shop that’s a strategic investor, is perfecting what it calls its DynaKinetic engine. Because it has no pistons and no valves and valve seats that would degrade without lubrication, it can easily run on liquid or gaseous fuels, including gasoline, diesel, propane, natural gas or even, in the future, hydrogen.

GoTek CEO Steve Herbruck said that a typical pickup using the DynaKinetic engine could get over 30 miles to the gallon while still being able to haul a boat with ease and switch among fuels.

“If you can’t find natural gas, you push a button and switch over to gasoline,” Herbruck told the Business Times. He said the company’s goal is to improve on all the areas of a piston engine, whether it’s fuel economy, power and torque, weight and size, emissions, reliability or serviceability. “We started the whole project because we cared about taking a bite out of our foreign oil dependency.”

While there are dozens of companies working on new rotary engine designs, one of GoTek’s biggest direct competitors might prove to be pre-existing notions about rotary engines — specifically, the Wankel engine used by Mazda for decades, most recently in its RX-7 and RX-8 sports cars.

All the rage when it debuted in the 1960s and renowned for the amount of smooth power it could produce in a lightweight package, the Wankel eventually developed a bad rap. To meet tightening emissions standards, engineers took some short cuts that resulted in poor fuel economy. But the worst problem with the Wankel was reliability. Because of a problem with internal seals, the engine developed a reputation for needing a rebuild every 60,000 miles.

GoTek’s leaders are emphatic that their design is not a Mazda Wankel engine and does not share that design’s limitations. They say they have solved the older Mazda rotary engine problems of high fuel consumption, low torque, and seal durability while retaining what was good — light weight and few moving parts.

“They tried and tried and tried, but the Mazda Wankel engine never took over the piston engine market,” said GoTek Executive Vice President and automotive industry veteran Scott Farrenkopf. “If you look at the different kinds of engines out there, Steve took a turbine engine, a piston engine, and a Mazda rotary Wankel engine and leveraged the best of all three by combining them.”

GoTek’s engine is about 70 percent lighter than an equivalent piston engine. It also runs at half the revolutions per minute of an equivalent piston engine, which translates to durability gains. GoTek believes it will also be more cost effective and simpler to make than piston engines plus easier to service and replace. Farrenkopf said it can be rebuilt in the engine compartment without removing intake, exhaust, and electrical systems.

“Our engine only has 13 moving parts for a four-chamber engine, as opposed to 54 moving parts for a four-cylinder piston engine,” Farrenkopf said.

GoTek has raised money from friends, family, and a few strategic investors such as Oxnard-based Willis Machine, where the company makes parts for testing and development. The company is currently working to complete statistical performance testing of its engine.

The company said it will probably target stationary engine applications for engine-generator sets and transportation refrigeration units as well as driving it with an electric motor and using it in the compressor and pump market before pursuing the mobile engine market. Stationary engine, pump and compressor customers can integrate a new design into products much faster than car or truck makers, who can take three to five years years to adopt new mobile engines.

For now, the company is working to make sure that the engine design is optimized for mass production and that it definitively solves the known problems of the Wankel engine before hitting the market. Herbruck said the company doesn’t want to come out with a new engine which is not fully refined or fails to exceed customer expectations. If GoTek isn’t satisfied, he said, the company will make a design improvement and create a better revised engine.

“We have standards we want to meet to make sure that when it comes out, it’s the best it can be,” Herbruck said.